| This documentation is out of date.

The new version of the documentation is here: https://cannylogic.com/docs |

Difference between revisions of "CANNY 7"

| [unchecked revision] | [unchecked revision] |

(→EEPROM Non-volatile Memory) |

(→Infrared Remote Control Driver) |

||

| Line 224: | Line 224: | ||

:''Main article'': '''[[CANNY 7, IRRC Driver]]''' | :''Main article'': '''[[CANNY 7, IRRC Driver]]''' | ||

| − | + | CANNY 7 controller can receive and send infrared remote controls commands (IRRC) in popular formats- NEC and extended NEC. Driver operation is possible in three modes: reception only,transmission only or reception / transmission. For transmission and reception any two channels used. | |

| − | + | When transmitting infrared remote control commands, channel used for this only generates baseband signal. To generate pulse packet, controller requires a carrier frequency, the source of which can be internal high frequency PWM channel or external PWM generator. Receiving IR command requires an external demodulator, such as TSOP1736 or similar. | |

| − | + | ||

| − | + | IRRC driver in its operation uses the resources of controller channels, but has a higher priority than discrete input-output driver. Thus, upon IRRC driver activation, for the involved channels in its operation, changing values in registers associated controllers' discrete input-output driver will be ignored. | |

== Specifications == | == Specifications == | ||

Revision as of 04:33, 30 December 2015

CANNY 7 — miniature programmable logic controller designed for automotive, domestic and industrial use.

Contents

General Information

Due to limited external channels, programmable logic controller CANNY7 may be attributed to a class of smart relays or Nano PLC. CANNY7 is capable of solving many automation, controlling and monitoring tasks.

CANNY7 is the first programmable logic controller oriented for automotive applications, with the following unique features and combination:

- rated power supply and IO channels voltage 0 / 12V (18V max);

- the maximum output current of each of the 11 IO channels +/- 120mA, sufficient to control usual automotive relay;

- CAN 2.0B Interface, compliant with ISO-11898, SAE J2411 widely used in modern cars;

- built-in energy consumption management in the range of 5 to 60 mA, helps to conserve battery power during period of inactivity in a car;

- EEPROM for applications and sixty-four 16-bit non-volatile memory data cells, available to user application to preserve critical data during a power failure;

- wide operating temperature ranged from -40 to + 85 ° C;

- Integrated surge protection and short circuit protection

- compact housing compliant to IP50 enclosure protection specification, suitable for installation and operation as part of a car cabin equipment;

- specialised packages of system and application software to use with automotive CAN and LIN networks.

To develop custom software for CANNY7, use graphical programming language CFD to quickly create user-effective applications- Functional Diagrams. Free IDE CannyLab contains tools for editing, debugging and writing software to the controller.

Requirements for writing software to the controller:

- PC with a USB port version 1.1 or higher

- Installed CannyLab environment

- Ordinary miniUSB cable

Controllers' memory acessible to user is enough to accommodate the program, consisting of several hundred functional blocks, which allows for fairly sophisticated algorithms. Each of the 11 IO channels are able to operate in any of the 98 modes that define the voltage, current, and temporal parameters of the input and output signals. In addition, some of the channels can be configured to operate in digital mode, to transmit / receive data of such protocols as 1-Wire, I2C, RS-232, LIN, CAN. The configuration of each channel can be set and adjusted from the user application. Two-coloured LEDs, controlled from the user application, are useful to indicate controller or debugging mode.

Design and functional operation

The appearance and layout

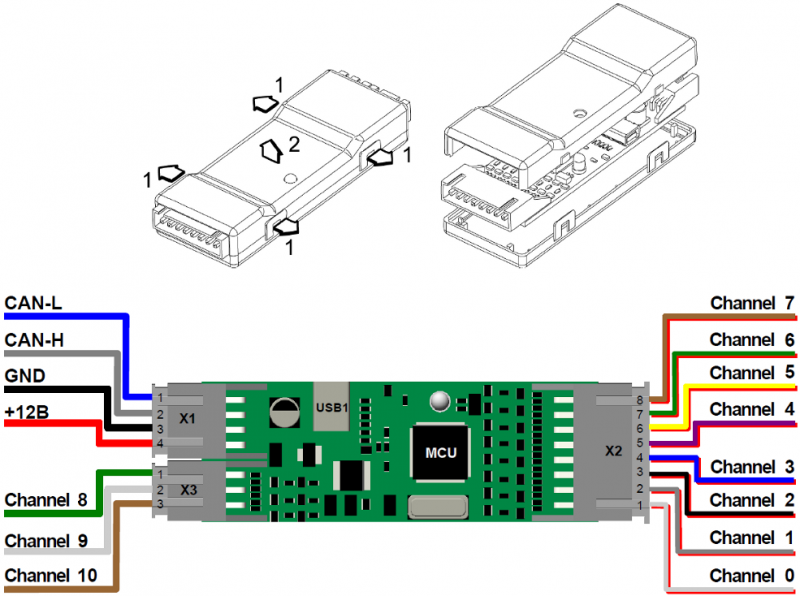

The main components of CANNY 7 are: a micro controller (MCU) with the auxiliary circuits, power supply system for all controllers' elements, IO channels level matching circuit, electric protection system, connectors and LED, based on a single print board 65 x 23 mm mounted inside a quick-open plastic casing. The controller has three external connectors and one internal. To connect the controller to the power supply and external devices, the kit includes a set of jumper harness.

- External connector X1 contains four terminals: + 12V input, power input GND, CAN-H and CAN-L.

- External connector X2 contains eight terminals, corresponding to the first eight channels of the controller, from №0 to №7.

- External connector X3 has three terminals, channels accordingly- №8, №9 and №10. Internal connector USB1 is to connect controller to the PC with miniUSB cable.

Software Architecture

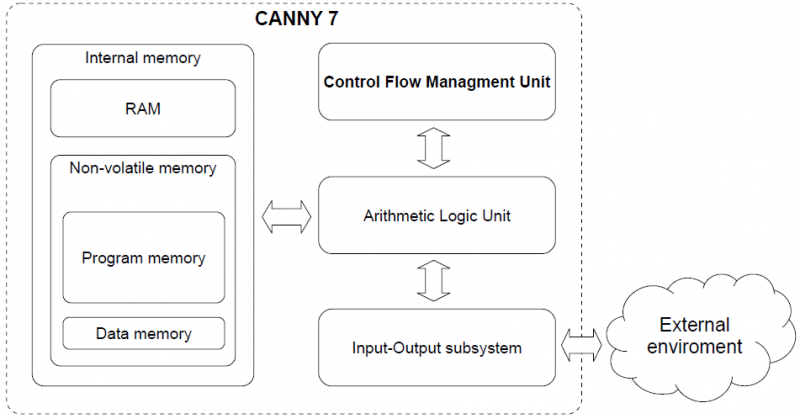

CANNY 7 is a digital programmable computing control device. CANNY 7 main elements are: arithmetic logic unit (ALU), internal memory, commands execution management subsystem and input-output system.

Arithmetic Logic Unit is the processing core of CANNY 7. ALU provides system software and user functional execution diagram placed into the internal memory of the controller. Controller's internal memory is divided into the EEP program memory, EEP data memory, and ROM. The command's management subsystem is responsible for switching and setting mode of the controller. The IO system provides controllers' communication to the outside world, using both discrete IO channels and standard digital interfaces CAN / LIN / RS232 / USB.

Software Structure

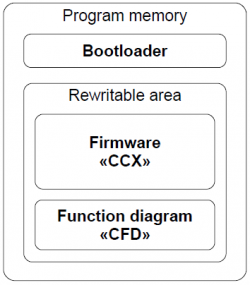

Software CANNY 7 consists of: a software loader, system software (operating system and driver), and a custom function diagram.

The program loader provides the controller with the software download mode, organising data transmission between CANNY 7 and PC using USB protocol. It checks the data integrity transmitted from the PC and loading to the controllers' internal memory. The software loader placed into the internal memory of the controller during production and can not be deleted or modified by the user. The manufacturer distributes CANNY 7 system software in CCX file format. It includes an operating system and a set of drivers providing function diagram execution and its interaction with the controllers' resources. User is restricted to modify system data file. The contents of various PCX files can be reloaded into the controller by user.

Custom block diagram is created and modified in integrated development environment CannyLab, then it can be loaded into the controller where it specifies the algorithm to work standalone or saved in to CFD file.

Operation modes

There are several operation modes to perform basic operations with controller.

Software download mode

In this mode, the controller is running boot loader to load system software, and functional blocks under CannyLab management. Controller switch to this mode automatically when connected to PC with USB cable. During the transition to SW download mode the controller performs a master reset: the functional diagram execution stops, IO channels are switching to neutral state, built-in green LED turns on. When controller establishes communicating with the PC software, the green LED goes into a flickering mode. Exit from this mode happens automatically when the connection to the PC is disrupted. If at the end of the software download mode , EEPROM have system software loaded correctly, the controller will switch to standalone mode, otherwise it returns to the download mode.

Autonomous mode

Standalone mode is the main controllers' mode. In this mode, the controller is running continuously under system software sequence, in an endless cycle, performing the functional diagram, working on the algorithm specified by the user. Transition to this mode takes place automatically when the controller is connected to an external 12V power supply and the absence of the USB connection. When operating in this mode, the functional diagram has access to all resources of the controller and drivers included in the system software when loaded.

Sleep mode

This mode is an option of normal standalone mode in which, after each cycle of execution of a function diagram, the controller pauses to reduce its power consumption to a minimum. Thus, the controller operates in a pulsed mode, periodically "asleep" and "waking up". Enable, disable, and configure the parameters of this mode are controlled by the functional diagram. Using this mode is relevant when developing systems, focused on battery-power, such as the on-board car equipment.

Runtime Environment

Functional diagram presentation

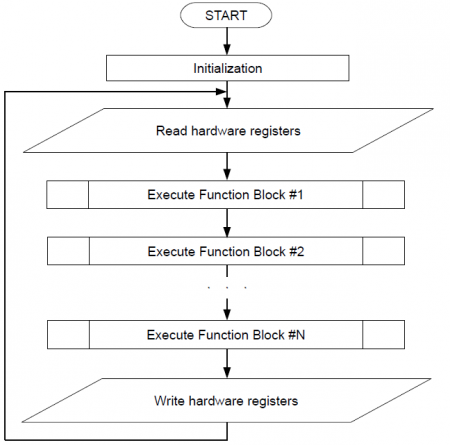

The graphical block diagram developed in CannyLab environment, automatically processed by the translator just before loading to the controller. CannyLab checks on the consistency of the diagram, determines function blocks execution order and converts the diagram into the executable code - a sequence of machine instructions CANNY 7 controllers' ALU.

The execution order

Executable program code during loading into the controller already contained system software, is including in the sequence of the system software machine instructions. Thus, the aggregate command sequence loaded with system software and functional diagram, will be: initialisation routines executed once after each controllers' reset and executable functional diagram code, framed with the controller resources' procedure management, and placed in an infinite executable loop - diagrams running loop. Some of the drivers included in the controller system software, such as CAN driver, require controller to raise immediate response during data transmission and reception of program events. Program code of these drivers asynchronously processed by the controller in parallel with the main execution flow. In the processing of asynchronous drivers calls, the diagrams main run loop performance is briefly suspended.

Access to hardware resources

All available resources to the user from the functional diagram : the system resources of the controller, IO subsystem and additional drivers included in the system software, appears on a controllers' internal memory protected address space. This address space is divided into read registers (control) and recording registers.

The user is able to specify the reading register address as a source of input data from virtually any function block of a diagram. Thereby extract and use to implement their own algorithms, data received by the controller from the outside world. For example information about the electric potential on any controllers' terminal, or the data packet contents received from the CAN bus. Recording register address can be used as the output recipient for any functional block on the diagram.Thus, the user controls the resources of the controller from functional diagrams which gives an opportunity to influence the objects of the outside world. For example: switch external relay by changing the electrical potential on one of the pins of the controller, turn LED on; set CAN operation mode; send a data packet.

The most resources used includes assignment required operating parameters, such as the polarity of the output channels, the polarity and the sensitivity of the input channels, CAN communication speed and so on.

Specifying these parameters is made in the form of recording specific constants in one or a few specific registers, depending on а required set of resources configuration. For example, copying a constant with a value of 121 in the register located at 2432 address is set channel №0 to an output positive polarity mode.

In CannyLab environment, for user convenience, all the of the controllers' available registers are named, as well as all special constants that are used in interaction with the controllers' resources. Therefore, for CannyLab user this operation will look as setting the constants named "standard positive output" at the input of the function block "Copy" and setting the address with the name "channel №0 configuration register» at its output.

Having thus established channel №0 mode, by the appearance of the value "1" in the register located at 2465 address ("channel №0 input value register"), we can learn about the application of a positive electric potential to №1 terminal of X2 connector.

System Registers

System Registers

- Main article: CANNY 7, System Registers

System resources are divided into an address group of read registers and an address group of write registers. Referring to the given registers from the functional diagram, you can get demanding information for practical application about the current status of the controller, and control its operation mode. The list of system resources registers located in the "State of the controller" addresses directory CannyLab, which is available to the user via IO context menu "Address" type of the function blocks.

Discrete Inputs and Outputs

- Main article: CANNY 7, Discrete IO Driver

CANNY 7 users have access to eleven discrete general purpose IO channels . Each channel is physically available through corresponding pins of X2 and X3 connectors . Writing and reading data of the respective drivers registers , the functional diagram can manage the electric potential in each of these contacts and getting information about the current potential of each of them. The channel physical characteristics allow connection to a variety of external actuators such as: electromagnetic relays, small motors, LEDs. As an external digital input signal, it is possible to use a mechanical, electromechanical, and electronic buttons and switches, pulse generators, voltage source 0-12V and transistor outputs of various equipment , etc.

Channels operation mode and parameters specified by function diagram. At any given time, the channel can only work in one of the possible modes, but it is possible to dynamic override the channel configuration from the functional diagram in the process of its execution.

High Resolution PWM

- Main article: CANNY 7, HR PWM Driver

Two of the eleven IO channels (Channel №1 and №2) CANNY 7 are able to work in high-resolution pulse-width modulator mode. The channels may be activated independently of each other and have a configuration independent duty cycle and line pull-up, however, the high-resolution PWM period is a common parameter to both channels. In HR PWM mode, the PWM timing parameters - the period and duty cycle are set in the range of from 2 to 20,000 microseconds, in 1 microsecond increments.

HR PWM channel has a fixed pulse polarity - GND 100mA. Generation can be conducted in either open collector (no pull-up or external pull-up) or with the internal pull-up to +12V (specified by setting value in the appropriate register ). In this mode, the channel is asynchronous to functional diagram, which allows for maximum stability of generated signal timing parameters.

| Note: | In the high-resolution pulse width modulator the electrical short circuit protection is disabled! Overload or channels short circuit being in RF PWM mode can cause damage to controller! |

UART / RS232 / Modbus driver

- Main article: CANNY 7, UART Driver

Two of eleven IO channels (#9 and #10) CANNY 7 supports UART, RS-232 serial protocols data transmission/reception. It may be used to connect the controllers with each other or with external equipment supporting this communications protocols. The channels may be activated independently of each other and have individual data speed setting, protocol type and configuration, pull up line.

UART implementation in CANNY 7 controllers allows to organize serial data reception and transmission over a single wire in half-duplex mode. Thus CANNY7 may have two independent connections using the UART protocol. Monitoring of the data link status should be done from the functional diagram. If the channel is free, the device may start data transmitting , otherwise the device should wait for the line release.

RS-232 implementation by using both UART data channels , allows to exchange data with other RS-232 device in a duplex mode, i.e. one channel to perform data sending and on the other to simultaneously receive data.

Modbus protocol in CANNY7 controllers implemented as over UART as over RS-232. As ADU (Application Data Unit) used compact binary option Modbus RTU. Checking the data integrity carried out by automatically calculated checksum (CRC). Package size is limited to 16 bytes including the CRC.

| Note: | For correct operation of all protocols based on the UART / RS-232 requires that all GND terminals of the devices committing communication, were given to a single potential ("common ground"). |

| Note: | In UART implementation-active line is the potential GND 100mA, passive - positive potential of a given internal or external channel pull-up. In implementing RS-232 - the potentials inverse. |

Driver UART/RS-232/Modbus operates using controllers' channels resources, but has a higher priority than a discrete input-output driver. Thus, upon activation of UART/RS-232/Modbus driver, for channels involved in its operation, a value changes in registers associated with discrete input-output driver, will be ignored.

CAN driver

- Main article: CANNY 7, CAN Driver

Two special external terminals of CANNY 7 controller, located on the 4 pin connector: CAN-H and CAN-L, designed for connection to digital information CAN-bus.

LIN driver

- Main article: CANNY 7, LIN Driver

Two of eleven input-output channels of CANNY 7, which can be placed under control of UART/RS-232 driver (Channel №9 and №10), can be used to organize data reception and transmission as two independent LIN driver channels.

LIN driver channels can be connect both together and individually, have individual baud rate settings , pull-up line and bus node type- MASTER or SLAVE.

LIN driver in its operation uses the resources of controller channels, but has a higher priority than discrete input-output driver. Thus, upon LIN driver activation, for the involved channels in its operation, changing values in registers associated controllers' discrete input-output driver will be ignored.

I²C driver

- Main article: CANNY 7, I²C Driver

As communication lines (SDA and SCL) can be assigned any pair of channels CANNY 7 controller. At the same time, these channels should be pulled-up to 5V with resistor 1 - 10k Ohm from the outside. The peculiarity of I²C protocol implementation is that CANNY 7 controller can act only as a Master node. Data exchange between devices, that can be both single and bi directional, takes place in separate sessions, i. e. opening multiple sessions with different devices is not allowed. The maximum length of the message within one session I²C of 16 bytes. Exchange rate is fixed to 100 kbit/s. The total number of slaves on the line can reach several tens.

Driver I²C operates using controller channels' resources , but has a higher priority than discrete input-output driver. Thus, upon activation I²C driver, for channels involved in to its operation, change values in associated registers of discrete input-output driver, will be ignored.

Dallas 1-Wire driver

- Main article: CANNY 7, Dallas 1-Wire Driver

CANNY 7 controller can be used as a MASTER in a single-wire data network Dallas® 1-Wire®.

Any of CANNY 7 input-output channels can be used to connect the controller to 1-Wire bus. At the same time, that channel must be externally pulled-up to 5V with resistor 3-7k Ohm. Consistently reassigning driver channels, it's possible to arrange up to 11 independent connections 1-Wire. Wherein device addressing and device handling by address is not available, therefore, in 1-Wire mode it is possible to connect only one SLAVE node at a time to controllers' channel.

Driver Dallas 1-Wire in its operation uses controller channels' resources, but has a higher priority than discrete input-output driver.Thus, upon activation Dallas 1-Wire driver, for channels involved in to its operation, change values in associated registers of discrete input-output driver will be ignored.

User Preprogrammed Parameters

- Main article: CANNY 7, User Preprogrammed Parameters

The custom configuration parameters can be specified by the end user at the time the controller loading a software using Firmware Update Utility. After software downloading and controller run in standalone mode, parametrs set by user so, become available in the relevant functional diagram of the controller registers.

Proper use of user-defined parameters significantly increases the flexibility and versatility of the controller-based solutions, enabling the end user without the skills to work with CannyLab, make safe changes in controller operation algorithm, using a simple user interface.

EEPROM Non-volatile Memory

- Main article: CANNY 7, EEPROM

To eliminate loss of critical information (state of the controller, external devices status, and so on..) I case of power reset , CANNY7 controller equipped with non-volatile memory. The values saved in EEPROM will be available in special registers after the power is restored.

There are 64 16-bit non-volatile memory cells, which are accessed by corresponding read and write registers.

| Note: | Working with non-volatile memory does not require any special pre-configuration. |

Infrared Remote Control Driver

- Main article: CANNY 7, IRRC Driver

CANNY 7 controller can receive and send infrared remote controls commands (IRRC) in popular formats- NEC and extended NEC. Driver operation is possible in three modes: reception only,transmission only or reception / transmission. For transmission and reception any two channels used.

When transmitting infrared remote control commands, channel used for this only generates baseband signal. To generate pulse packet, controller requires a carrier frequency, the source of which can be internal high frequency PWM channel or external PWM generator. Receiving IR command requires an external demodulator, such as TSOP1736 or similar.

IRRC driver in its operation uses the resources of controller channels, but has a higher priority than discrete input-output driver. Thus, upon IRRC driver activation, for the involved channels in its operation, changing values in registers associated controllers' discrete input-output driver will be ignored.

Specifications

Electrical characteristics and environmental requirements

| Напряжение питания | 9...18 В | |

| Потребляемый ток: | в рабочем режиме (не более) | 55 мА |

| в энергосберегающем режиме (не более) | 5,5 мА | |

| Максимальный ток каждого канала в режиме выхода | +120 мА / -120 мА | |

| Сопротивление канала в режиме входа | 4 кОм или 200 кОм | |

| Диапазон рабочих температур | -40оС...+85оС | |

| Степень защищенности от пыли и влаги | IP50 | |

Защита электрических цепей:

- от короткого замыкания канала — программная;

- от перегрузки канала — внутренними токоограничительными сгораемыми резисторами;

- от смены полярности источника питания — внутренним диодом;

- схема подавления высоковольтных выбросов при коммутации индукционной нагрузки каналов с №0 по №7: диод и варистор;

- схема подавления высоковольтных выбросов при коммутации индукционной нагрузки каналов с №8 по №10 — отсутствует.

Safety Precautions

В цепях контроллера отсутствует опасное для жизни обслуживающего персонала напряжение. Открытые контакты контроллера при эксплуатации находятся под напряжением. Любые подключения к контроллеру и работы по его техническому обслуживанию производятся только при отключенном питании контроллера и подключенных к нему устройств.

Installation and connection

Монтаж и подключение контроллера должны производиться только квалифицированными специалистами, изучившими настоящую документацию. Монтаж контроллера должен производиться в местах соответствующих требованиям к условиям эксплуатации контроллера.

Не допускается попадание влаги на контакты выходных соединителей и внутренние элементы контроллера. Запрещается использование контроллера при наличии в атмосфере кислот, щелочей и иных агрессивных веществ.

Установка контроллера и прокладка кабелей подключаемых к нему должна производиться на расстоянии не менее 0.3 метра от высоковольтных силовых линий и источников сильных электромагнитных излучений — мощных реле, контакторов, газоразрядных ламп. Не допускается попадания влаги на корпус контроллера в месте его установки.

Transportation and storage

Контроллеры транспортируются всеми видами закрытого транспорта. Размещение и крепление транспортной тары с упакованными устройствами в транспортных средствах должны обеспечивать их устойчивое положение и не допускать перемещений во время транспортирования.

Транспортирование и хранение должны осуществляться при температуре окружающего воздуха от минус -40 до +85 °С и относительной влажности воздуха – до 80%, с соблюдением мер защиты от ударов и вибраций. В воздухе не должны присутствовать кислоты, щелочи и иные агрессивные вещества. Контроллеры следует хранить на стеллажах.